Covertec Double membrane roof

The Covertec double membrane roof is an innovative, premium-quality roof system for the biogas industry. The system comprises two separate membranes manufactured from polyester woven fabric, PVC-coated on both sides, with a minimum weight of 27 oz/yd² (900 g/m²) and a minimum tear resistance of 900 lbs per 2 in. (4,000 N per 5 cm). The double-layer assembly is designed to even out pressure fluctuations in the container while the hemispherical and rotunda shape serves to maximize storage capacity. At the same time, the domed surface protects the cover against external weather action, such as heavy snow loads in winter.

Features

High-tech membranes with minimum weight of 27 oz/yd² (900 g/m2 )

Stainless-steel clamping strip connections

Integral supporting air blower with stainless-steel weather cover and outlet valve in external membrane

Supporting construction comprising custom-developed, low-strain straps and desulphurization mesh

Visual gas level indicator

Rainwater deflector and edge cover to protect top edge of container

Pressure safety valve (35,315 ft³/h) (1,000 m3/h flow rate) with integral condensate ring to reduce risk of freezing in winter

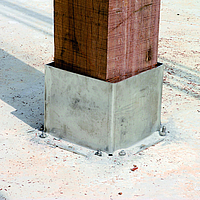

Central column in hardwood or stainless steel, as required

Operating pressure of 0.05 psi (+3.5 mbar), designed for short-term peaks up to 0.15 psi (+10 mbar)

Why choose Covertec double membrane roofs?

Low gas permeability, maximum gas storage capacity, extremely high UV stability and high tear resistance are just some of the benefits offered by the Covertec double membrane roof. Manufactured in diameters of up to 148 ft (45 m), they offer reliable protection against snow loads. Moreover, all Covertec double membrane roofs are provided with a five-year warranty.

We would be glad to perform a project- and site-specific structural calculation on your behalf. On request, we will also carry out the full installation (incl. provision of work platforms and cranes).

The package covers all system components, including central column, supporting strap construction, air blower, gas level indicator and pressure safety device.

Variants

The standard silo cover with gas-tight lung is a gas-tight model incorporating a sheet „lung“ for the storage of gas produced by any type of organic substrate. The cover is clamped to the internal face of the silo to produce a gas-tight seal. With the premium-grade model, the gas-tight seal is positioned on the top edge of the container, thus allowing the cover to be removed even when the silo is full.

The standard silo cover with gas-tight lung is a gas-tight model incorporating a sheet „lung“ for the storage of gas produced by any type of organic substrate. The cover is clamped to the internal face of the silo to produce a gas-tight seal. With the premium-grade model, the gas-tight seal is positioned on the top edge of the container, thus allowing the cover to be removed even when the silo is full.